Coiled Tubing Services

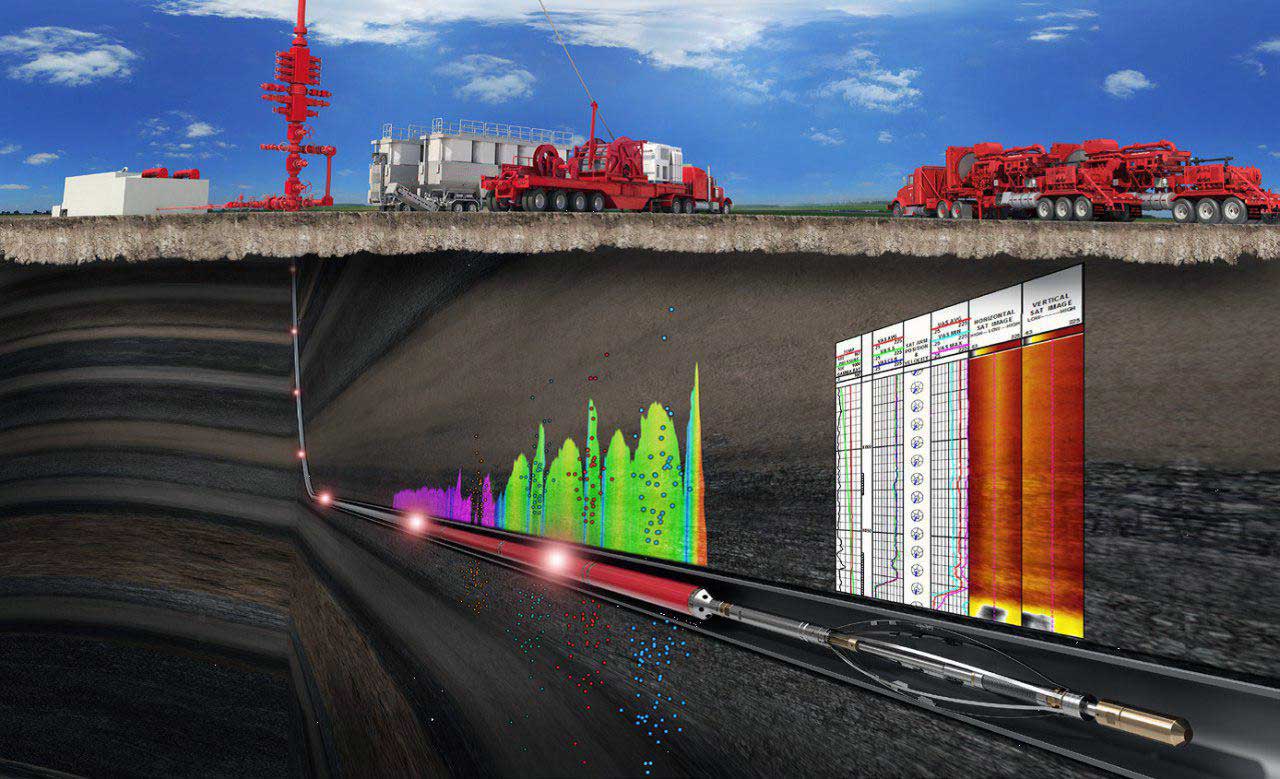

SeaLand provides coiled tubing services for both well intervention and new well completion programs for some of the largest and most active oil and gas producers in North America.

Onshore and offshore, SeaLand combines well-maintained, state-of-the-art coiled tubing and pumping equipment with expert personnel who have decades of experience. The result is consistent, competitive solutions delivered safely and in compliance with environmental regulations.

SeaLand utilizes NOV’s Cerberus modeling software to help accurately predict and analyze cumulative forces at each stage of a coiled tubing job. Cerberus is the industry standard software for planning and performing well intervention services.

Cerberus Modeling Software includes:

- Orpheus (Tubing Forces)

- Reel-Trak (Reel time fatigue tracking)

- Hydra (Hydraulics)

- Achilles (Fatigue Life)

During execution of CT jobs, the parameters are recorded with NOV’s OrionNET software. The software is touch-screen compatible and can display the data in real time either locally or remotely.

- OrionNET IV & V Data Acquisition

For advanced design considerations, SeaLand can use Baker Hughes’ CIRCA Pro Coiled Tubing Simulation Software. Refined over more than three decades, CIRCA Complete software provides the industry’s most accurate modeling of tubing forces, pressures, friction losses, rheologies, fluid behaviors, and downhole tool operations. The software is capable of analyzing solids cleanout to ensure effective circulation and removal of the debris.

Apart from tracking the coiled tubing string’s life, SeaLand has a corrosion management program that eliminate sulfate reducing bacteria (SRB) in recirculated fluids. Year to date, SeaLand has not had a SRB related failure in over 5 yrs. Due in part to our bacteria management program.

SeaLand Services maintains a fleet of fifteen (15) coiled tubing packages, each package with additional support equipment consisting of high pressure fluid pumping units as well as nitrogen equipment.

- Coiled Tubing pipe size capabilities from 1.25” CT to 2.625” CT

Solutions

- Acidizing / Fracturing / Nitrogen Kick Off

- Sand or Fill Clean Out

- Pumping Cement Slurry Plugs

- Scale Removal (Hydro-Jetting)

- Fishing or Retrieving Plugs / Packers

- Drilling / Milling (Hard Scale or Bridge Plugs)

- Tubular Cutter

- Permanent Coiled Tubing Installation (Completion, Velocity String)

- Selective Zone Isolation and Setting Packers

- E-Line Logging and Perforation Applications

- Complete data acquisition, real-time fatigue monitoring and tubing forces modelling software packages

- Fiber Optic Coiled Tubing

Equipment and Resources

- 240, 480, 580, 680 and 5100 injector heads

- 1 1/4 “ to 2 7/8” tubing capacities

- Coiled Tubing Units

- Pumping Units

Flow Back Unit